Metal Stamping

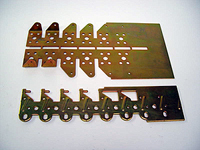

Metal stamped custom parts and components

What is Metal Stamping?

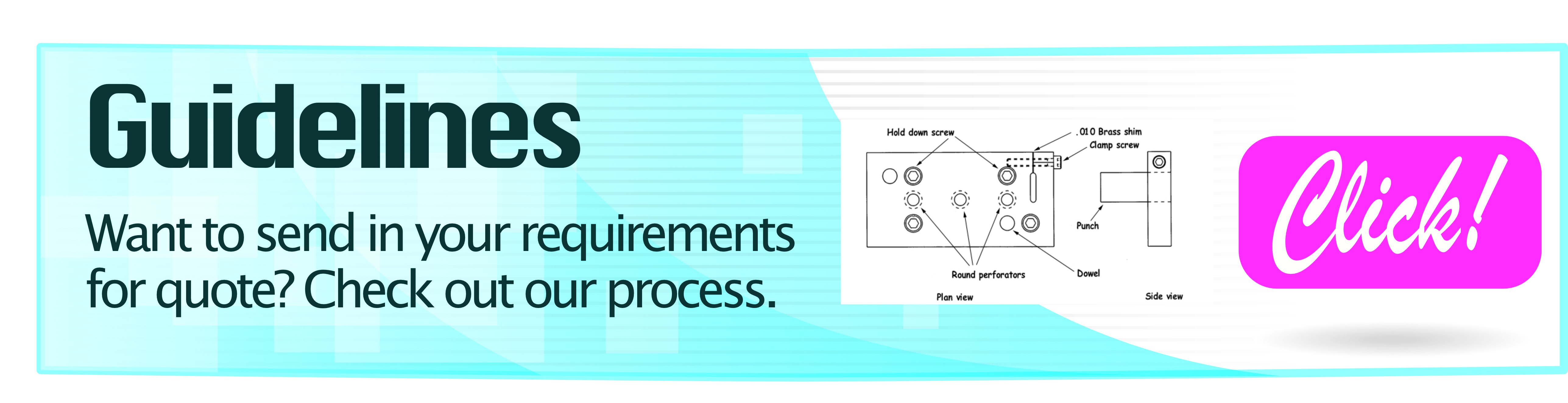

Stamping or also know as pressing is a process of placing coil or flat sheet metal into a stamping press to be formed by a die, the surface of the die will form the raw stock into the desired form and it does this by striking the material. The stamping press can exert tons of pressure in a single strike, and as the press works the material is fed into the area where the stamping die is fastened to the press bed.

Helfrich Tool excels in producing a limitless variety and sizes of custom stamped metal parts used in industrial and commercial assemblies, all made to your exact specifications.

Key Stamping Benefits Include

Guaranteed Die Tooling part production to match precise tool specifications

Sheet - Steel - Brass - Stainless Steel - Copper - Galvanized - Aluminum - Spring Steel - Woven Wire Mesh

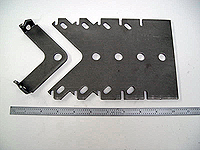

Metal Stamping Tolerance to ± .003

Metal Stamping Depth Drawn to 3.00"

Stamped Thickness .005 to .375

Metal Stamping Diameters up to 16"

Prototype to Production capabilities, run length from 10 parts to millions of parts custom metal stamped and formed metal parts, consistent quality through first article inspection, in process inspection and final inspection.

Pricing based on the custom metal stamping quantity ordered, tooling required and the lead time necessary for on time delivery.

Get Quote / Contact UsWhether your part is metal sheet stamping or in Steel, Stainless, Aluminum, Brass, Copper or Wire Cloth our company can provide you with impeccable quality stamping services. Call us for your next custom stamping, forming, piercing, bending offsetting, drawing quotation.

© Helfrich Tool and Die Corporation